Our people: Sung Park

Laboratory technician Sung Park prepares oil samples for fault gas testing.

Enlarge image: Laboratory technician prepares oil sample in a syringe.

A transformer blows, causing an outage to the surrounding area. Our field staff rush into the Selkirk Lab with oil samples from the transformer. They need to know if it’s safe to reenergize, and they need to know yesterday.

That’s where Sung Park comes in. The syringe containing the oil sample is handed off to Sung or another laboratory technician. He performs an oil test to determine if it’s safe to reenergize the transformer. If a transformer is faulting, an oil test detects certain dissolved gases. If that happens, the transformer needs to be serviced and possibly replaced.

If the transformer is leaking, Manitoba Hydro lab technicians perform another test to determine if the oil contains PCBs (toxic chemicals). This test informs the method of cleanup to best reduce environmental impact.

Sung and his fellow lab staff across the province are commonly involved in transformer outages, like when a large pole fell on a station transformer in St. Laurent in February or when a vehicle collided with a transformer in Winnipeg. Chemical lab staff are on-call 24/7/365 to perform testing to ensure reliable power to Manitobans, yet never in the public eye.

Large pole with a broken base damages a station transformer in St. Laurent.

“My friends sometimes ask me why I work as a chemist for Manitoba Hydro,” said Sung. “‘Hydro is an energy company, why would they need chemists?’”

“Some people see a chair and they only think about the area you sit on,” he said. “Meanwhile there are nails, there are legs, there are small parts to connect them together. If you do not have each of these parts, it will all fail. Chemical Lab Services is one of those parts in Manitoba Hydro. It couldn’t do anything by itself, but if you don’t have it, then we couldn’t be providing reliable energy.”

“You could say the same about lots of departments in Hydro.”

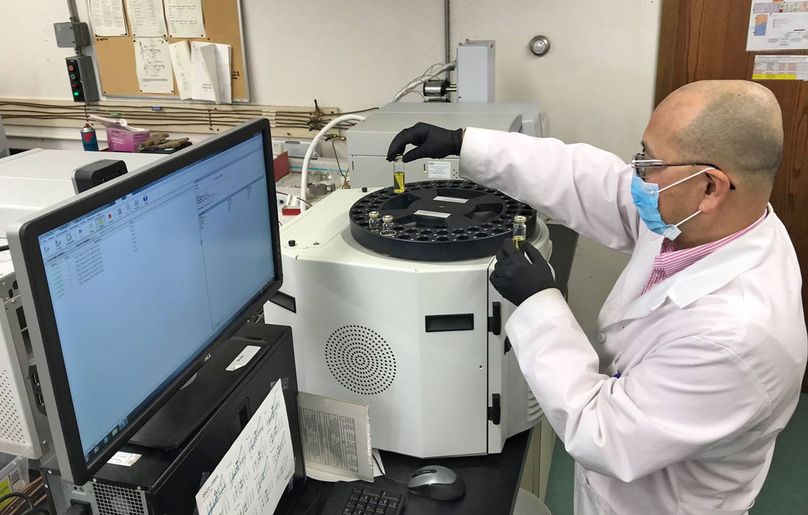

Sung places oil samples on an autosampler coupled to a Gas Chromatograph. It detects the fault gases in transformer oil.

Enlarge image: Laboratory technician places an oil sample on a lab machine.

Not just emergency tests

Just like your car, transformers need to have their oil changed. The difference is, many of the transformers at our stations hold more than 50,000 litres of oil and can last decades without needing to have their oil replaced.

Besides emergency situations, Sung performs tests for our routine oil sampling program. Part of regular transformer maintenance has field staff bring oil samples to our labs (Brandon, Selkirk, and Waverley). Oil testing is a way for electrical engineers to tell if a transformer is about to fail and needs to be replaced, and when it just needs an oil change.

“An engineer once told me the oil sampling program is Manitoba Hydro’s cheapest insurance program,” said Mark Dalmaijer (Chemical Lab Services). “It’s a simple and non-intrusive way to assess the lifespan of the transformer.”

How has the pandemic affected work?

Staff in the lab are frontline workers. They cannot bring all the lab machinery home, so they follow all pandemic protocols to reduce the risk of transmission.

“It’s a weird environment because although we are seeing each other, we are conscious of keeping a distance from each other and trying to avoid talking as much as possible to lower the risk of transmission.” said Sung. “When I do talk, wearing a mask means I may have to repeat things a few times, especially because English is not my first language.”

“The new normal means we’re adjusting and improvising, because we are an essential service and the work has to get done one way or another.”