Forest fires and pole fires are a yearly concern, so people are always asking the inevitable question: “why are we still using wood poles for distribution lines?”

Historically we have used wood poles because wood is a renewable, abundant, strong, and inexpensive material. Due the history of using wood, engineers have a very good understanding of its material properties and how it will behave in different environments.

Darryl Orr, an engineer who works with standards and materials, said, “The wood pole is a naturally a strong material that is easy to modify, climb, treat with pesticides, and is inexpensive relative to the other options available. It is also a renewable resource and naturally sequesters carbon during its development.“

“The primary aspect of wood poles is that they can easily be modified and adapted. It can be cut, drilled, and treated using tools found in local hardware stores. Even isolated and remote areas will likely have access to the tools necessary to modify a wood pole as needed,“ said Darryl.

“A wood pole is also easy to work on. With our existing equipment (e.g. a belt and spurs) a Power Line Technician (PLT) can move around a pole into any position they need to be in while working. This makes it easier to install or fix and replace insulators, conductors or other equipment. Most other pole materials require fixed steps to be installed or ladders to be used.“

The good ol’ wood pole

Wood also has advantages during installation and replacement work. “An inexpensive and robust wood pole allows for quick reconstruction with minimal equipment and tooling.

“There are no long delays waiting for any concrete base to cure, and reduced issues with a heavy material failing over in wet ground due to the weak holding power of soil.

“Wood poles can be transported by helicopter to remote or isolated areas, where heavier steel or laminate poles may require a winter road or other special accommodations to get them in place.“

Also considered is that the province has too many different climatic and environmental factors at play — factors that may destroy, damage or weaken materials, or limit the use of one material or another.

Enlarge image: Wood poles lying on the ground in a laydown area, as employees work on them.

Manitoba Hydro needs poles that can be used for both permanent and temporary fixes. A universally acceptable material allows us to respond to these conditions anywhere in the province.

However, modern alternatives are not outside consideration. “We understand the drawbacks of using wood. They can burn and are susceptible to rot and insects if not properly treated. Since it is a natural product, defects can be hidden to the eye. Wood poles are also easier to damage — by woodpeckers, for example, and even by larger wildlife using wood poles to sharpen their claws or scratch an itch.“

Darryl said that fibreglass poles may be a modern contender for wood pole replacement as it would survive more of these extreme situations and is light and robust.

“Still, other materials are not as economical to use — typically more than 3 times the price of wood poles. But, as climate change and invasive pests are making the harvesting of wood more difficult and increasing wood pole pricing, the price difference between wood and other materials is shrinking.

“We also have to factor in other materials’ disadvantages. Some require special tooling or machines to install, making them difficult to use in many areas. Fibreglass and other materials are not easy to work with, making it more difficult for our line trades to do their work. This results in increased construction time and potential risk of injury.“

So, while wood is still a best option overall, Manitoba Hydro has tested or is using many of the alternatives to wood poles.

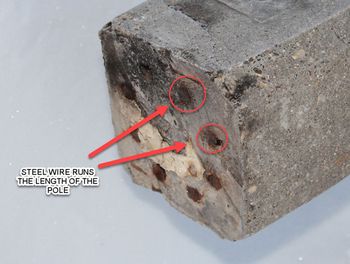

Cross section of a concrete pole.

Enlarge image: Cross section of a concrete pole showing the steel rods used inside the concrete.

Scorch marks on a concrete pole from an electric arc.

Enlarge image: A concrete pole with blackened areas around some of the holes drilled into it.

Concrete poles have been installed in our system since the 1970’s, in the Winnipeg and Brandon areas. These poles have stood the test of time, but due to an arc flash incident involving the poles — and other complications such as difficulty climbing and the inability to modify the pole — concrete is not a viable alternative at this time.

Laminate poles are used today as switch poles and corner structures (ones that do not require guy-wires). You can see one on the southwest corner of Waverly and Wilkes in Winnipeg and a couple of switch poles are located on Waverley just south of Abinojii Mikanah Boulevard (formerly Bishop Grandin), on the east side. Due to the additional costs when compared to wood poles, as well as the difficulty in climbing laminate poles, these really are not a consideration for our everyday use.

Fibreglass poles have been approved for use after testing at the training center. A pilot project conducted several years ago has several poles installed in East Kildonan and there is a current project where they are being used for back yard distribution on Peony Avenue.

Composite/fibreglass pole sections lying on the ground before assembly

“We do have a contract now for fibreglass poles. Transmission poles (75 foot and larger) made of fibreglass are closer in price as wood pole prices have gone up.“

Steel has been used for years and has been a solid performer, there are several examples along Abinojii Mikanah Boulevard west of Pembina Highway. The time it takes to create a concrete base and the excessive costs make this a limited option for everyday use.

A composite/fibreglass pole being erected by a team.

Alternate pole material advantages and disadvantages

Fibreglass

Fibreglass

Advantages:

- Light weight and can be turned into sections so it can be moved by hand by a small crew.

- Strong.

- Flexible, while resisting related damage, so it can survive higher winds and more ice loading.

- Fire resistant.

- Insect and rot resistant.

- Lifespan is estimated to be over 100 years with minimal maintenance.

- Available in different colours.

Disadvantages:

- Expensive (3 to 4 times the price).

- Difficult to climb (it is harder to move around a pole to get into a good working position as climbing steps are in installed in fixed spots, i.e. you can’t climb or position your self using a belt & spurs). Additional steps may be added as required.

- Requires more expensive tooling. Carbide drills and saws are required as normal tooling used with wood poles would dull very fast when used in this material.

- Requires a filter mask during modifications, as fibreglass is a hazardous material to breath in (though not necessarily required if done outdoors and paying attention to wind direction).

- Will degrade in ultraviolet (UV) light. UV inhibitors are included in the resins or painted onto the pole which extends the lifespan, but this will eventually fail which will cause the pole to degrade.

Concrete

Concrete

Advantages:

- Strong.

- Resistant to fire, rot and insects.

- Lifespan is estimated to be about 70+ years depending on environment.

- Can have different colours.

Disadvantages:

- Expensive.

- Depending on design, they can be very heavy.

- Corrosion can easily happen in certain environments. Direct buried units (Poles where the steel is buried into the ground) may only last 15 to 25 years due to corrosion in some environments, even with external treatments. That is why we don’t use screw in piles or direct buried streetlights anymore.

- Difficult to climb or requires special climbing equipment depending on model.

- Does require special tooling for modification.

- Long time to construct, as concrete used for their base needs time to cure.

- Difficult, in remote or isolated areas, to construct as the heavy materials require larger, more expensive equipment for installation and transportation.

- The pole is very conductive. This increases the probability of an unintentional energization or an arc flash incident happening.

- Attracts lightning.

Steel

Steel

Advantages:

- Strong.

- Resistant to small fires, though very hot fires will cause it to anneal (lose strength) or fail.

- Lifespan is 70+ years depending on environment.

- A well understood engineering material.

- Fairly easy to modify.

- Resistant to insects.

Disadvantages:

- Expensive.

- Depending on design, they can be very heavy.

- Corrosion can easily happen in certain environments. Direct buried units (Poles where the steel is buried into the ground) may only last 15 to 25 years due to corrosion in some environments, even with external treatments. That is why we don’t use screw in piles or direct buried streetlights anymore.

- Difficult to climb or requires special climbing equipment depending on model.

- Does require special tooling for modification.

- Long time to construct, as concrete used for their base needs time to cure.

- Difficult, in remote or isolated areas, to construct as the heavy materials require larger, more expensive equipment for installation and transportation.

- The pole is very conductive. This increases the probability of an unintentional energization or an arc flash incident happening.

- Attracts lightning.

Laminate

Laminate

Laminate poles are wood poles but are engineered from smaller pieces of wood that are glued together. Engineered poles are dimensionally consistent, meaning they do not shrink over time. This results in reduced radio interference complaints due to loosened hardware.

Depending on the model they have different advantages and disadvantages.

Advantages:

- Engineered, so there are no hidden flaws.

- Easy to modify, can drill and mount additional equipment or conductors.

- Made from renewable resources.

- Easy to treat for pests.

- Strong.

- 70-year life span.

Disadvantages:

- Can be heavy and large.

- Their rectangular shape is difficult to climb.

- Can rot and be susceptible to insects and other pests.

- Can burn.

- May require specialized equipment for installation depending on size.