Sometimes you just have to make noise.

Implosion sleeves and why we use them

Filmed this spring: crews from Brandon and Dauphin used implosion sleeves for a transmission structure in Brandon — and yes, it’s even louder than it looks.

Implosion sleeves are often used to crimp two lines together. This time, they were used on dead-end terminals — basically a metal tab with bolt holes — that connect power lines to an insulator. Dead-end power lines might seem strange, but it’s just a workaround for changing directions. Since power lines can’t curve, dead-end structures like this one are how we get them to go another way. The line stops at an insulator, then a mid-air jumper line connects it to another line going a different direction.

A transmission line comes in one way, stops at an insulator connected to a pole, and a jumper line connects it to another line going in a different direction. All the lines are suspended and safely insulated from poles.

This dead-end structure was being replaced as part of our Integrated Pole Maintenance program — a cataloguing, maintenance, and refurbishment program for the wood poles that hold up power lines across the province. Before the implosion sleeves were brought in, the landscaping and grading around the structure was corrected for better water flow, new poles were set next to the old ones, and the old poles were sawed apart bit-by-bit to get them out of the way. Once the old poles are small enough, the line can be attached to the new poles. And then it’s detonation time.

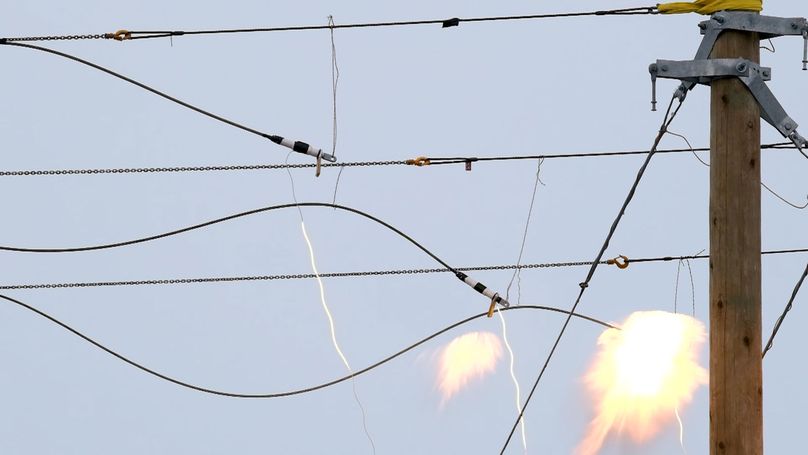

The moment before detonation on the transmission line.

The moment before detonation on the jumper line.

Whenever we use implosion sleeves, everyone around gets a warning. They make a loud bang and a flash like a firework, so it can be quite a shock if you’re not expecting it (during the filming process, our communications team learned it can also be a shock if you are expecting it). To make sure customers knew before we detonated these, we posted on social media, knocked on doors, and sent a media advisory to all the outlets in Brandon well in advance of the day we were using them.

In the end, there were three total detonations: six dead-end terminals on transmission lines, six jumper terminals for the jumper line, and a third blast to get rid of the remaining “fuse,” called shock tube, which is also explosive. For safety purposes, the implosion sleeves are stored in a secure facility elsewhere and are only brought in the day they’re needed. When the work is done, excess shock tube is detonated and its remains burned. Nothing is left behind but solid, permanent connections to power lines.